Rolex is Granted Patent for UItra-Smooth Curved Ceramic Axles

Rolex operates multiple scientific laboratories and is consistently granted more patents than any of their competitors. Rolex does a huge amount of research and development relating to advanced ceramic manufacturing in particular, and today they were granted a US patent regarding just that. US patent 12,055,893 B2 relates to the manufacturing of incredibly smooth rounded ceramic axles. Let’s quickly discuss what Rolex’s patent for producing a hyper-precise “surface of revolution” is all about.

Abstract

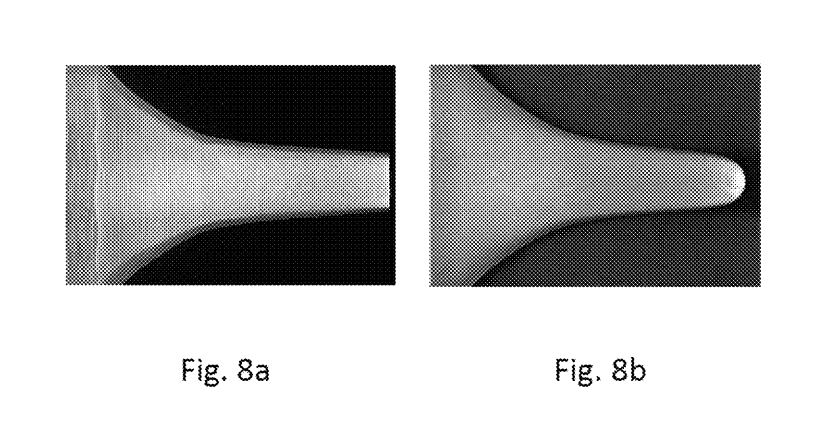

This Rolex patent (which is just the American version of a 2019 European patent) is for a two-step process, involving both femtosecond lasers and tribofinishing, to make an incredibly smooth (Ra value < 20nm) rounded ceramic clock arbor (watch axle). Here’s the full abstract of the patent:

Method for producing a surface of revolution of a clock or watch component comprising a step of machining, with a femtosecond laser beam, a first surface of the clock or watch component so as to obtain a second surface whose roughness (Ra) is less than 100 nm, or less than 70 nm, and then a tribofinishing step applied to the second surface so as to obtain the surface of revolution.

Rolex via the United States Patent Office

What is a Surface of Revolution?

A surface of revolution is a three-dimensional surface (generally smooth and curved) created by spinning an object on its axis against a curved plane. Basically, picture someone using their hands to shape a pot on a pottery wheel.

What is a Femtolaser?

A femtosecond laser is an extremely precise grade of laser that applies quadrillionth-of-a-second-blasts of energy. Rolex has already been using them to make laser-etched dials for years now. In this newly patented process, a femtosecond laser is used to first create a roughness average between 70-100nm, and then 10 hours of tribofinishing will get it under 20nm.

What is Tribofinishing?

Tribofinishing, also known as chemical-mechanical polishing, vibratory finishing or vibroabrasion, involves both mechanical and chemical actions to modify the surface state and edges of materials. The process typically includes the use of abrasive media. In this Rolex patent in particular, diamond particles on the scale of one micrometer are used!

What’s the Benefit?

The point of this patent is likely, simply, to reduce friction. Less friction means a more efficient watch movement, so this could theoretically lead to longer service intervals, higher power reserves, and/or higher amplitudes. An Ra value of 20nm for a watch component is truly impressive–when you get down to about 0.5nm, you’re talking about “manufacturing advanced modern semiconductors” levels of precision.

But just because Rolex patented something, doesn’t mean they’ll actually do it–at least anytime soon. They’ve been known to patent all sorts of cool stuff and then leave it on the shelf. Time will tell if these cool smooth ceramic arbors will reach production watches!

More on Rolex:

Women’s Rolex Watch Guide

Rolex Deepsea Guide: A Timeline of All Models

Best Rolex GMT-Master Alternatives

Five Possible 2024 Off-Catalog Rolex Models Revealed Via Swiss Design Patents

Rolex Milgauss Collector’s Guide

Leave a Reply