Rolex Pursues Patents for Bar-Turning Tiny Ceramic Watch Parts

In October 2025, four Rolex patent applications were published that all essentially describe the same thing: fashioning tiny watch parts from very hard materials with a high-rpm bar turning method. The conventional wisdom is that if you try to bar‑turn (meaning you work a bar through a spinning lathe) a block of something like ceramic at “normal” speeds (say 3,000-15,000 rpm) with a typical tool, you destroy cutters and parts in short order. So these materials are often machined with lasers, or worked in a “green” state–a non-final state of ceramic when it is more chalky and workable. But these 2025 Rolex patents mean we could see ceramic pinions, pivots and other parts machined from fully sintered ceramic (or other hard materials) soon.

What is the Real Innovation in the 2025 Rolex Bar-Turning Patents?

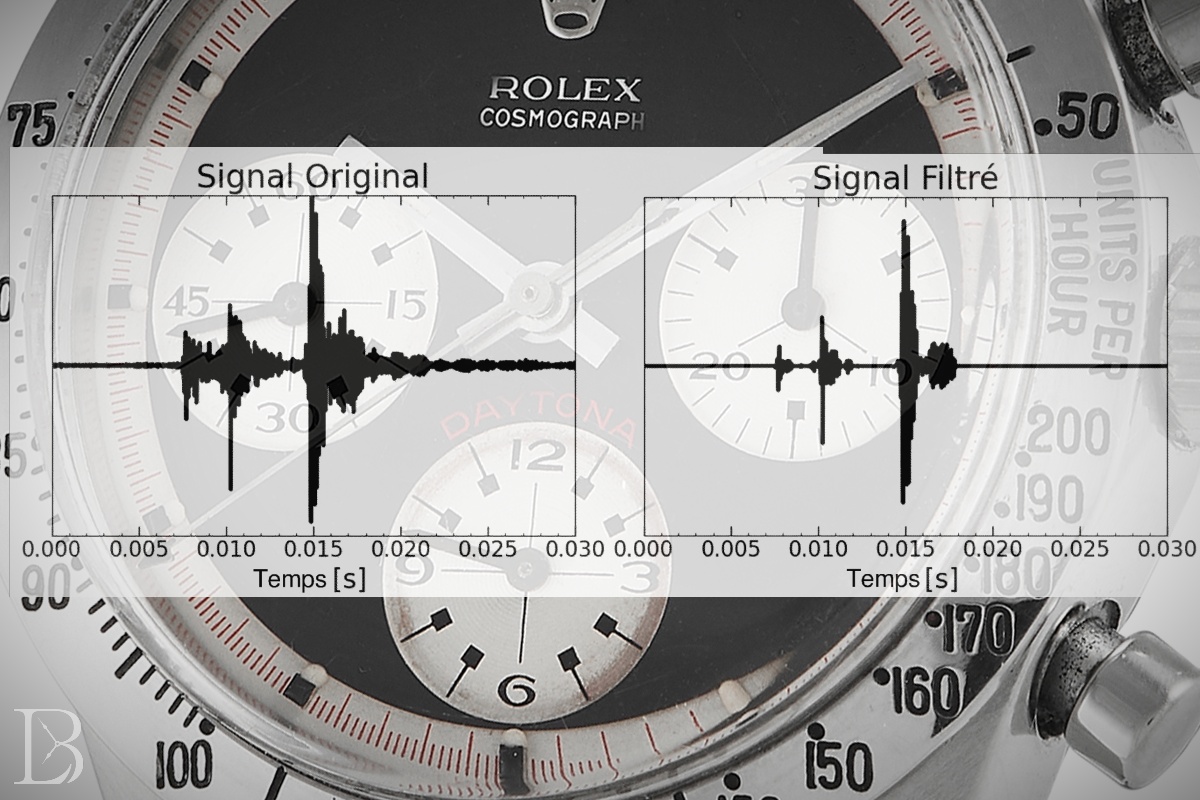

Well, the breakthrough really does seem to be pretty straightforward: spin your lathe and/or diamond-tipped cutting tool super fast–e.g. at least 20,000-40,000 rpm for the lathe and/or 100,000-180,000 rpm for the cutting tool. The result, unexpectedly, is actually reduced wear when machining hard materials. So you can cut ceramic (or other hard things) without breaking your tools, or your rod of material, like you would at lower speeds. With this tons-of-fast-little-cuts method, only a tiny chip is cut away with each pass, so nothing breaks–there are just a lot of chips being made.

What Parts Will Rolex Make with this Process?

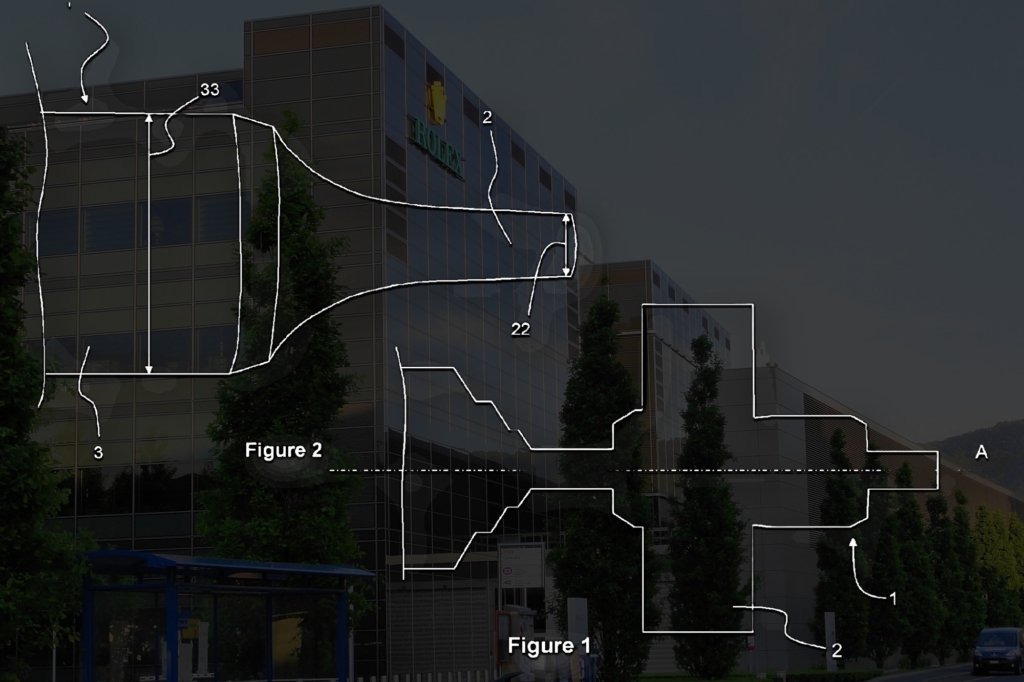

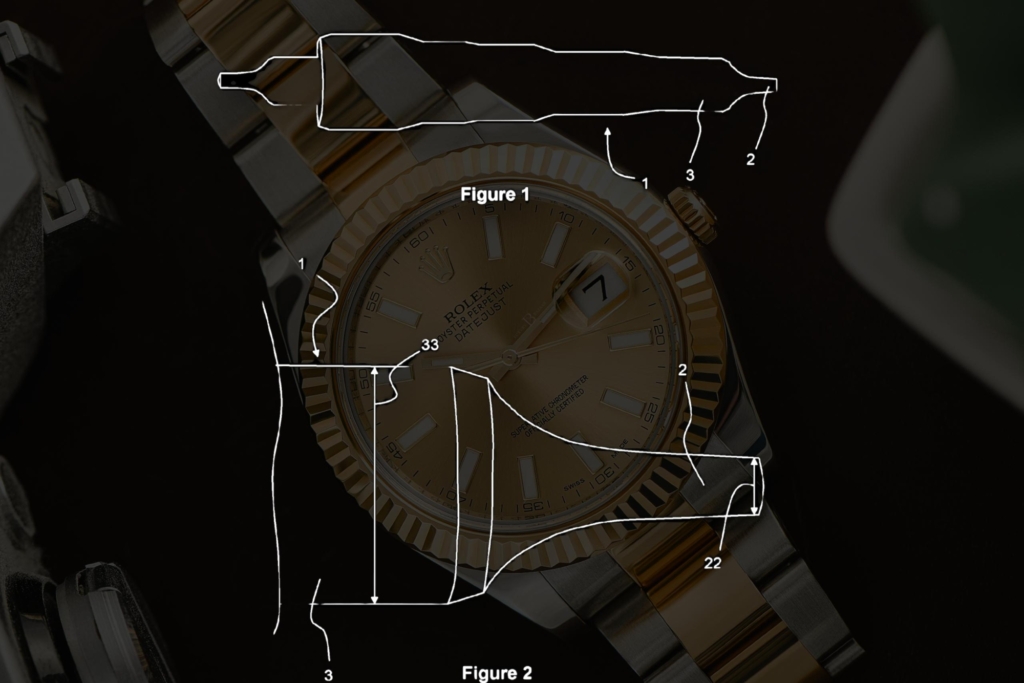

WO2025219459A1 focuses on pivots and WO2025219460A1 focuses on pinions, while WO2025219458A1 and WO2025219456A1 use more general language about “watch parts.” Note that these patents have not been granted; they’re all still pending.

In 2024, Rolex filed a patent for manufacturing arbors with femtolasers, so this isn’t their first foray into ultra-hard small watch parts.

Who Invented This?

The patents list Remo Pavone, Eric Morandi, Alexandre Neukomm, and Fabrice Droz as the four inventors responsible–all Swiss. Morandi’s name only appears on two of the patents, and those are the two that specifically mention using a tool at ultra-high rpm’s. So, I assume Morandi is the one who figured out that spinning the cutting tool extra fast (instead of the block/part to be machined) is also a viable method of shaping parts from extremely hard materials. Kudos all around.

Keep in mind that Rolex files a lot of patent applications–some for things they’ve already released, and some for things they’ll never release–so it doesn’t mean any new product is imminent. But it does mean that, as usual, Rolex is at the forefront of watchmaking materials technology. Even if that technology is just spinning something 5x faster than normal.

Leave a Reply