New Rolex Patent: Binary Hafnium Alloys with Dark Oxide Coatings

Rolex, as they frequently do, has once again received a patent related to manufacturing advanced materials. In November 2024, Rolex was granted US patent WO 2024/227680 A2 for a novel binary alloy made of either titanium-hafnium (Ti-Hf) or zirconium-hafnium (Zr-Hf), with a dark oxide layer on its surface. That thick oxide layer provides exceptional scratch resistance, while the underlying metal alloy retains more ductility than ceramics would. Plus it’s an interesting way to achieve a black-colored metal without a damage-prone surface coating like DLC, and Rolex can even adjust the density as needed. This technology will likely be used for both internal and external watch components. Let’s quickly break down Rolex’s new binary hafnium alloy patent.

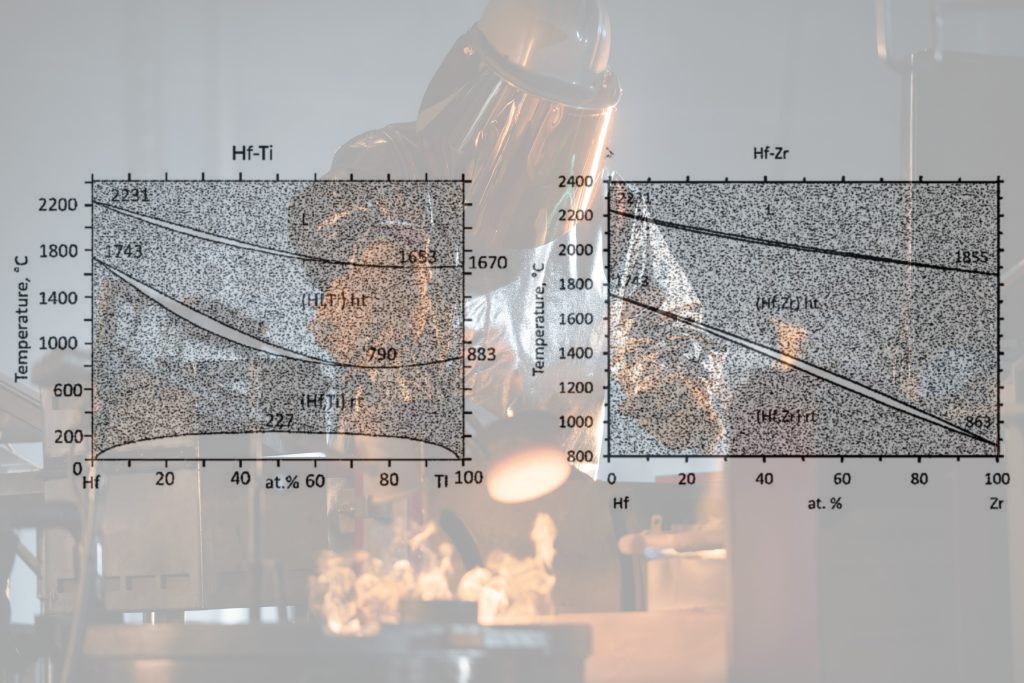

The use of hafnium in watchmaking is certainly novel, and Rolex seems to be achieving some very high hardness values with it. Rolex’s patent mentions a GPa value of at least 10 (maybe even over 13) which is comparable to ceramic. But both Ti-Hf and Zr-Hf are metal alloys, not ceramics. These are considered binary alloys because, simply, they have two elements. Rolex had previously patented a mix of all three (a ternary alloy), which produced a similar oxide surface layer but lacked the “variable density” aspect.

Variable Density

Arguably the most interesting aspect of this 2024 Rolex patent is the variable density of the alloy. By simply adjusting the amount of hafnium in the alloy (always at least 10%), Rolex can make its density anywhere from 7 to 12 g/cm³. So in theory, Rolex can dial in the exact ideal density of various watch components. Hafnium is about 4x more valuable than silver, so it’s not cheap, but it’s not exactly exotic either.

Colorization

The patent describes the outer dark oxide layer as “black or dark grey,” with “no or only very slight bluish tones.” The CIELab color values specified in the Rolex patent confirm that it would be fair to describe these heat-treated binary alloys as black, or close to it.

What Parts Will Be Made of These Patented Alloys?

This patent for Rolex binary alloys specifically mentions both interior and exterior watch components:

- Watch exterior components mentioned: Cases, bracelets, crowns, bezels, hands

- Watch movement components mentioned: Balance wheels, barrels, bridges, base plates, shafts, pinions

Black Rolex Watch Cases: Are They Coming?

Rolex has never made a watch with a ceramic case, nor a DLC-coated case, presumably because they’re simply not durable enough for Rolex’s standards. Ceramic can shatter or chip, and DLC coatings inevitably get scratched up. But a heat-treated Ti-Hf watch case should certainly be tough enough for Rolex. We won’t speculate too much about a possible black-case Rolex, but if they ever made one, this alloy seems perfect for it.

How Is the Outer Dark Oxide Layer Added?

The binary Ti-Hf and Zr-Hf alloys described in this patent don’t have coatings added in the traditional sense. Instead, the dark surface layer is formed through a process of controlled oxidation of the alloy itself. Here’s a breakdown of how this works:

- The alloy is first manufactured and shaped into the desired form (e.g., a watch case).

- The surface of the alloy is then subjected to “a heat treatment process in an oxygen-containing atmosphere at a temperature of 400 to 750°C.” This typically lasts 1-6 hours.

- During this heat treatment, oxygen reacts with the metals in the alloy, forming a thick oxide layer on the surface. This layer grows inward from the surface, creating what’s called a “conversion oxide layer.”

- The resulting oxide layer is described as “adherent, thick, hard and dark.” It’s not a separate coating, but rather an integral part of the alloy’s surface that has been chemically transformed.

The closest thing to these alloys in the luxury watch world today would probably be Panerai’s Ti-Ceramitech material. It also gains its dark, scratch-resistant outer layer via oxidation, but Panerai opts for plasma electrolytic oxidation instead of heat treatment. Rolex’s oxide layer is likely thicker.

How Thick is the Dark Oxide Layer on Rolex’s Patented Binary Hafnium Alloys?

According to Rolex’s patent, these binary hafnium alloys will develop oxide layers between 5 and 25 microns thick. For reference, anodized titanium can get up to about 5 microns at most. Pure titanium (e.g. grade 2 titanium) and popular titanium alloys (e.g. grade 5 titanium) have natural oxide layers of about 0.01 microns or less. Gold plating typically ranges from 0.5 to 2.5 microns, so as a crude frame of reference, the oxide layer on these alloys is about 10x as thick as a layer of gold plating.

Magnetic Resistance

Rolex’s patent refers to these alloys as paramagnetic, meaning they can be weakly attracted to magnets, but the metal itself won’t “become magnetized.” That doesn’t mean this is a sign of a revived Rolex Milgauss, because after all, even regular titanium is paramagnetic. But it is just another reason that these heat-treated binary hafnium alloys are well-suited to watchmaking all around.

It’s worth noting that Rolex often registers patents and then doesn’t use them for years, if ever. So don’t get your hopes up if you’ve been itching for a factory black-case Rolex Submariner anytime soon. But maybe, just maybe, Rolex has something interesting up their sleeve.

Leave a Reply